Internet of Things Role in The 7 Waste Efficiency of Lean Manufacture

Internet of Things Role in The 7 Waste Efficiency of Lean Manufacture

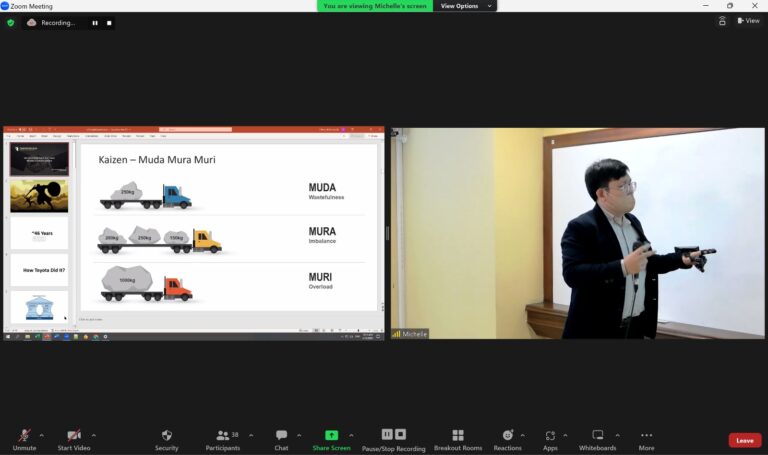

Industrial forum MTD, BASE, BOL, TD organized a workshop with the topic “Internet of Things Role in The 7 Wasre Efficiency of Lean Manufacture”.

The event presented speakers namely Randy Budi Wicaksono, S.Si., M.Sc. as the President Director of PT Ravelware Technology Indonesia and Mr. Amir Tjolleng, Ph.D. from Associate Lecturer Specialist S3 Industrial Engineering Department – Binus University as the moderator.

The discussion focused on the efficiency of lean manufacturing where a good company should not have too much inventory, because it will become waste. Toyota is one of the companies that has almost no waste, because Toyota has a goal of high quality, with the lowest cost but with a short lead time.

Toyota implements the Just-In-Time system and also Jidoka. The Jidoka system is implemented by Toyota to reduce the occurrence of errors, defects or production errors. The concept of Jidoka is to immediately stop the work/process when errors are found in the process, so that defects can be avoided.

The 7 wastes that need to be avoided are:

Inventory -> raw materials, work in progress or finished goods which do not have value added to it.

Movement -> unnecessary movement of people within a process.

Waiting -> people or parts that wait for a work cycle to be completed.

Overproduction -> to produce sooner, faster or in greater quantities than the customer demands.

Overprocessing -> processing beyond the standards required by the customer.

Defects -> not right first time, repetition or correction of a process.

Transportation -> unnecessary movement of things (parts or machines) between processes.

Currently, Toyota has implemented IoT in its production process. Industry 4.0 is a mindset that says that machines and humans can work together, to make faster decisions. When it comes to IoT, it is more advanced because it deals with hardware, sensors, processes, etc.

In the Internet of Things, there are main layers. Where the business layer is part of system management, then the application layer represents graphic data including smart applications. Middleware layer is a process information, such as decision unit data analytics. Next is the network layer which is data transmission. The last layer is the perception layer such as physical objects sensors & actuators which are data gathering. Although IoT has 5 layers, the core of IoT is only 2, namely hardware and software.

According to Joerg Grafe, Senior Market Analyst, IBM “The Internet of Things is the game-changer for an overall business ecosystem transformation”. IoT cannot be said to be cheap or expensive because IoT depends on the needs of the company itself and also how the impact will be given if the company implements IoT in its company.

There are past and future in maintenance, as follows:

Reactive Maintenance: corrective maintenance that happens after a breakdown.

Preventive Maintenance: regularly performed maintenance to reduce failures.

Predictive Maintenance: using sensors and software to predict future failures.

Perspective Maintenance: machine learning helps predict failures and identify solutions.

IoT is not only applied to the production process but also to logistics. Currently, the use of RFID is also applied to logistics systems. Using IoT in logistics can improve inventory management, less manhour needed, less human error, better accuracy, data-driven decision making.

Conclusion of Internet of Things Role in The 7 Waste Efficiency of Lean Manufacture

1. The 7 wastes of lean manufacturing are transportation, inventory, motion, waiting, overproduction, overprocessing, defects.

2. Return on investment: expensive or cheap price of IoT system is totally depends on the merits. Usually, 2 years of break even is the average used by the company.

3. Next trend, then: Toyota production system and now: Industry 4.0 (still ongoing)

Comments :