How Industrial Engineering Is Leading the Global Manufacturing Shift in 2026

(Source: automotiveengineeringhq.com)

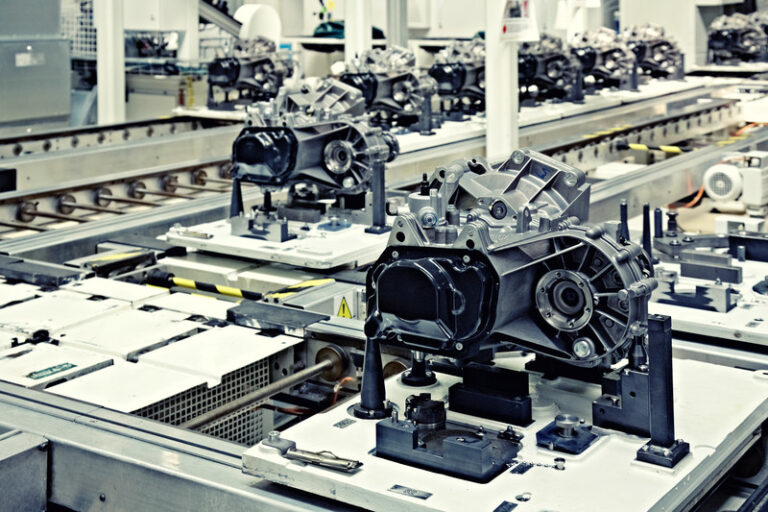

Industrial Engineering at the Heart of a New Manufacturing Era

In 2026, the world is witnessing a fundamental transformation in how products are made, distributed, and consumed. Manufacturing is evolving rapidly due to advancements in artificial intelligence (AI), persistent global labor shortages, and urgent environmental demands. Amidst these pressures, industrial engineering (IE) is emerging as a key driver in redefining production systems, increasing resilience, and ensuring sustainable, cost-effective operations.

The role of industrial engineers today extends far beyond factory floors. They are optimizing supply chains, integrating smart systems, and building processes that are adaptable in real time. From the headlines of Foxconn’s billion-dollar smart factory in Vietnam to global efforts in automating production lines while maintaining human value, industrial engineers are not just reacting to change—they are designing it.

This article explores how industrial engineering is leading the global manufacturing shift in 2026, grounded in recent events, real-world examples, and the evolving challenges industries face today.

The Expanding Role of Industrial Engineers

Traditionally, industrial engineers focused on reducing waste, improving efficiency, and streamlining operations. But the world of 2026 demands more. With rising complexity in global manufacturing systems, IEs are expected to operate as systems architects, data analysts, sustainability strategists, and cross-functional innovators.

They are working with AI teams to integrate machine learning into supply chain forecasting. They’re involved in corporate-level decisions on technology adoption. And more than ever, they’re playing a central role in sustainability strategies, ensuring that automation doesn’t just cut costs—it reduces carbon emissions and improves ethical labor standards.

As manufacturing moves toward more agile, real-time operations, the ability of industrial engineers to coordinate multiple moving parts—from humans to machines to data flows—is proving to be irreplaceable.

January 2026 Headlines: A Turning Point for Manufacturing

This January, leading global news sources reported a series of groundbreaking shifts in manufacturing. These reports highlight the growing significance of industrial engineering in navigating this transition:

-

Bloomberg (January 12, 2026): “AI Adoption Accelerates as Manufacturing Labor Crisis Deepens Across Asia and Europe.”

-

Reuters (January 18, 2026): “Foxconn Announces $1.2 Billion Investment in Smart Factory Expansion in Vietnam.”

-

CNBC (January 25, 2026): “Robots Are Filling Labor Gaps, but Workflow Optimization Still a Bottleneck.”

These developments are not isolated. They signal a global movement where automation, AI, and smart systems are being embraced not just to enhance productivity, but to overcome critical structural challenges—from workforce shortages to unstable supply chains. Industrial engineers are at the center of this evolution, reconfiguring operations to align with rapidly changing technologies and expectations.

AI Integration: Building Smart, Adaptable Production Systems

Artificial intelligence has shifted from experimental to essential in manufacturing. In 2026, smart factories are becoming the norm, not the exception. But while AI brings the promise of speed, accuracy, and data insight, it also introduces complexity.

Industrial engineers are vital in transforming this complexity into coherence. They are responsible for:

-

Identifying which processes benefit most from AI integration

-

Creating logic flows and feedback systems that allow machines to “learn” effectively

-

Ensuring AI does not disrupt existing human roles but complements them

For example, in automotive plants, AI-driven vision systems now inspect products in milliseconds with nearly flawless precision. But without the right process design—timing, coordination, exception handling—those systems can lead to delays or false errors. IEs build the framework that ensures AI systems contribute to overall process efficiency rather than creating new challenges.

Solving the Labor Shortage Through Smarter Systems

One of the most significant manufacturing challenges of 2026 is the persistent labor shortage. Despite increasing automation, companies still struggle to find skilled workers to manage complex systems, handle unpredictable tasks, or supervise AI-assisted operations.

Industrial engineers are leading the charge in solving this issue without reducing human involvement. Their strategies include:

-

Designing user-friendly machine interfaces that reduce training time

-

Splitting tasks into manageable roles that can be quickly upskilled

-

Implementing ergonomic solutions to retain aging workers

In Germany, an electronics plant reengineered by a team of industrial engineers showed a 30% increase in workforce efficiency, even with 15% fewer staff, simply by optimizing workstation layouts and introducing collaborative robots (cobots) to handle repetitive strain tasks.

By blending technology with human-centric design, IEs are preserving the value of the workforce while helping manufacturers remain competitive.

Smart Manufacturing and the Rise of Industry 4.0

Industry 4.0 represents the convergence of IoT, robotics, AI, and cloud systems. But implementing Industry 4.0 technologies is more than a tech upgrade—it’s a full operational transformation. Industrial engineers are the facilitators of this change.

They’re tasked with:

-

Creating data integration plans between equipment, cloud services, and dashboards

-

Coordinating logistics and inventory to adapt to real-time data flows

-

Managing cybersecurity risks in increasingly connected environments

In Poland, a 2026 project by ABB featured real-time machine-to-cloud communication that allowed engineers to adjust factory operations from a central digital control room, based on performance data gathered every second. This level of efficiency and agility would not be possible without detailed system planning—crafted by industrial engineers.

Case Study: Foxconn’s Smart Factory in Vietnam

One of the most talked-about manufacturing developments this January was Foxconn’s $1.2 billion investment in a new smart factory in Bac Giang, Vietnam. Set to become one of the most advanced electronics manufacturing hubs in Asia, this facility is being designed from the ground up with industrial engineering principles.

Foxconn has publicly stated that:

-

The plant will feature fully autonomous assembly lines

-

Over 3,000 sensors will monitor real-time performance

-

The layout is being designed to support continuous flow production with minimal downtime

The project’s success will depend largely on the capabilities of industrial engineers to synchronize machinery, labor, materials, and software platforms into a seamless operation. This example underscores how IEs are no longer just participants—they are the architects of global manufacturing’s future.

Cost Optimization During Technological Transitions

As manufacturers race to adopt AI, robotics, and smart systems, cost management has become more complex than ever. In 2026, cost optimization is no longer about simple expense reduction. Instead, it is a strategic effort to balance technology investment, operational efficiency, and long-term resilience. This is another area where industrial engineering plays a decisive role.

When new technologies are introduced, hidden costs often emerge. These include system integration delays, employee retraining, temporary productivity losses, and increased maintenance complexity. Without proper planning, these costs can erode the expected benefits of automation. Industrial engineers approach this challenge systematically. They evaluate total system cost rather than isolated expenses, ensuring that each technological upgrade contributes measurable value.

For instance, before implementing advanced robotics, industrial engineers frequently run process simulations to test different scenarios. These simulations help identify the most cost-effective layout, optimal production rates, and potential failure points. According to a January 2026 analysis published by McKinsey Operations, manufacturers that applied industrial engineering methods during digital transitions reduced implementation costs by an average of 20% compared to those that adopted technology without system-level optimization.

Cost optimization, therefore, becomes a continuous process rather than a one-time decision. By aligning financial planning with process design, industrial engineers help organizations remain competitive even as manufacturing technologies evolve rapidly.

References:

- Bloomberg. (2026). AI Adoption Accelerates as Manufacturing Labor Crisis Deepens Across Asia and Europe.

- Reuters. (2026). Foxconn Announces $1.2 Billion Investment in Smart Factory Expansion in Vietnam.

- World Economic Forum. (2026). The Future of Jobs in Advanced Manufacturing.

- McKinsey & Company. (2026). Digital Operations and Cost Optimization in Manufacturing.

- Deloitte. (2026). Building Resilient Supply Chains in a Volatile World.

Comments :